10 Best Enterprise Construction ERP Software in India (2026 Updated List)

Table of Contents

Introduction: Why Construction Companies Need ERP in 2026

How We Selected the Top Construction ERPs (Evaluation Methodology)

Top 10 Best Enterprise Construction ERP Software in India — Full List

Comparison Table: Feature-by-Feature Review

Which ERP Is Best for Your Company Type? (EPC, Infra, Real Estate, RMC, MEP)

biCanvas — Why It Ranks #1 in 2026

Core Modules to Look For

Implementation Timeline & Rollout Speed

Total Cost of Ownership (TCO)

FAQ

Introduction: Why Construction Companies Need ERP in 2026

Enterprise construction projects in India are operationally complex:

Managing 20–200+ multi-site projects simultaneously

Daily WIP updates and BOQ alignment

Budget vs. actual tracking

Subcontractor billing and RA bills

Material planning and inventory reconciliation

Statutory compliance (GST, RERA)

Equipment lifecycle and preventive maintenance

Site-level reporting and coordination

Traditional tools like spreadsheets, WhatsApp updates, and manual reporting cannot handle this scale. Enterprise construction companies adopt ERP systems to:

Prevent cost overruns

Maintain project timelines

Ensure BOQ accuracy

Track inventory/materials

Improve billing predictability

Strengthen financial visibility

A well-implemented enterprise construction ERP becomes the operating backbone of mid-to-large construction businesses.

How We Selected the Top Construction ERPs

Our 2026 ranking uses a structured, industry-focused evaluation model based on 23 decision parameters.

A. Core Construction Functionality

WBS and project breakdown

BOQ management & version control

Procurement & indent workflows

WIP tracking and daily progress reporting

Subcontractor management and RA billing

DPR automation and site-level approvals

Budgeting, estimation & material reconciliation

B. Financial & Operational Control

Budget vs actual

Cost center tracking

Cash flow monitoring

Project-level P&L

GST, TDS, RERA compliance

C. Deployment & Scalability

Cloud performance & multi-project capability

Integration readiness (API, IoT, GPS, Tally, SAP)

Workflow automation & custom approval routing

D. Usability & Adoption

Mobile-first design

Offline data capture

UI/UX for site engineers

Training & support availability

E. Pricing & Total Cost of Ownership

Licensing flexibility

Implementation cost & support

Upgrade policy

Integration costs

Top 10 Best Enterprise Construction ERP Software in India (2026)

Note: The full list highlights enterprise-focused solutions for mid-to-large construction companies. biCanvas is positioned #1 for multi-site, EPC, and infrastructure projects.

biCanvas — Enterprise construction ERP for multi-site, EPC, and infrastructure firms

SAP S/4HANA (Construction) — Large-scale enterprise projects, multi-entity

Oracle Construction Cloud — Portfolio-heavy infrastructure and EPC

In4Suite (In4Velocity) — Real-estate focused, medium-to-large developers

Procore — Large project collaboration and field management

Farvision ERP — Residential developers, mid-to-large projects

CMiC — Enterprise project management, construction finance

Viewpoint — Construction accounting + project management

Builderstorm — Mid-to-large construction firms, modular

Maxwell ERP — RMC and precast-focused enterprise projects

Comparison Table — Feature-by-Feature Review

Capability / Feature

biCanvas (Enterprise)

In4Suite

SAP S/4HANA

Oracle Construction Cloud

Procore

BOQ & WBS Management

Native, versioned

Native

via PS/PSA

via modules

via integrations

WIP & DPR (real-time)

Mobile-first, offline

Mobile support

via integrations

Mobile

Mobile logs

Subcontractor RA Billing

Automated workflows

Native

via FI/PS

Limited

Limited

Procurement & Indent

Site/HO integrated

Yes

Yes

via partners

Yes

Inventory & Intersite Transfer

Location-aware

Yes

Yes

Partial

Limited

Equipment Lifecycle + IoT

Native + telematics

Add-on

Add-on

via partners

No

Workflow Builder

Visual, complex flows

Basic

Custom dev

Configurable

No

Multi-Entity Consolidation

Native

Yes

Yes

Yes

No

Implementation (Typical)

3–6 months pilot

2–6 months

6–18 months

4–12 months

3–9 months

Best Fit

Mid to Large enterprises

Mid to Enterprise

Large enterprise

Large infra & portfolios

Large projects

Legend:

Native/Strong — Core feature fully integrated

Add-on/Partner — Available via customization or third-party

Limited/No — Not available or severely restricted

Which ERP Is Best for Your Company Type?

A. Infrastructure & EPC

Needs: Complex scheduling, equipment fleets, mobilization planning, subcontractor billing, audit compliance

Recommendation: biCanvas — enterprise ERP for seamless WIP, accounting, and equipment integration. Primavera or scheduling add-ons may complement.

B. Real Estate / Residential Developers

Needs: Project accounting, CRM, sales-to-construction handover, post-sales service

Recommendation: biCanvas — integrated with CRM for end-to-end construction workflows. Alternatives: In4Suite, Farvision.

C. RMC & Construction Manufacturing

Needs: Plant production planning, batch traceability, inventory, logistics, integrated billing

Recommendation: biCanvas — with manufacturing connectors for RMC/precast operations. ERP platforms with manufacturing extensions may complement.

D. Large Contractors / Multi-Project Portfolios

Needs: Multi-entity consolidation, project-level P&L, intersite transfers, equipment utilization

Recommendation: biCanvas — best-in-class enterprise ERP for multi-project portfolios, real-time financials, and operational visibility. Alternatives: SAP S/4HANA, Oracle.

biCanvas — Why It Ranks #1

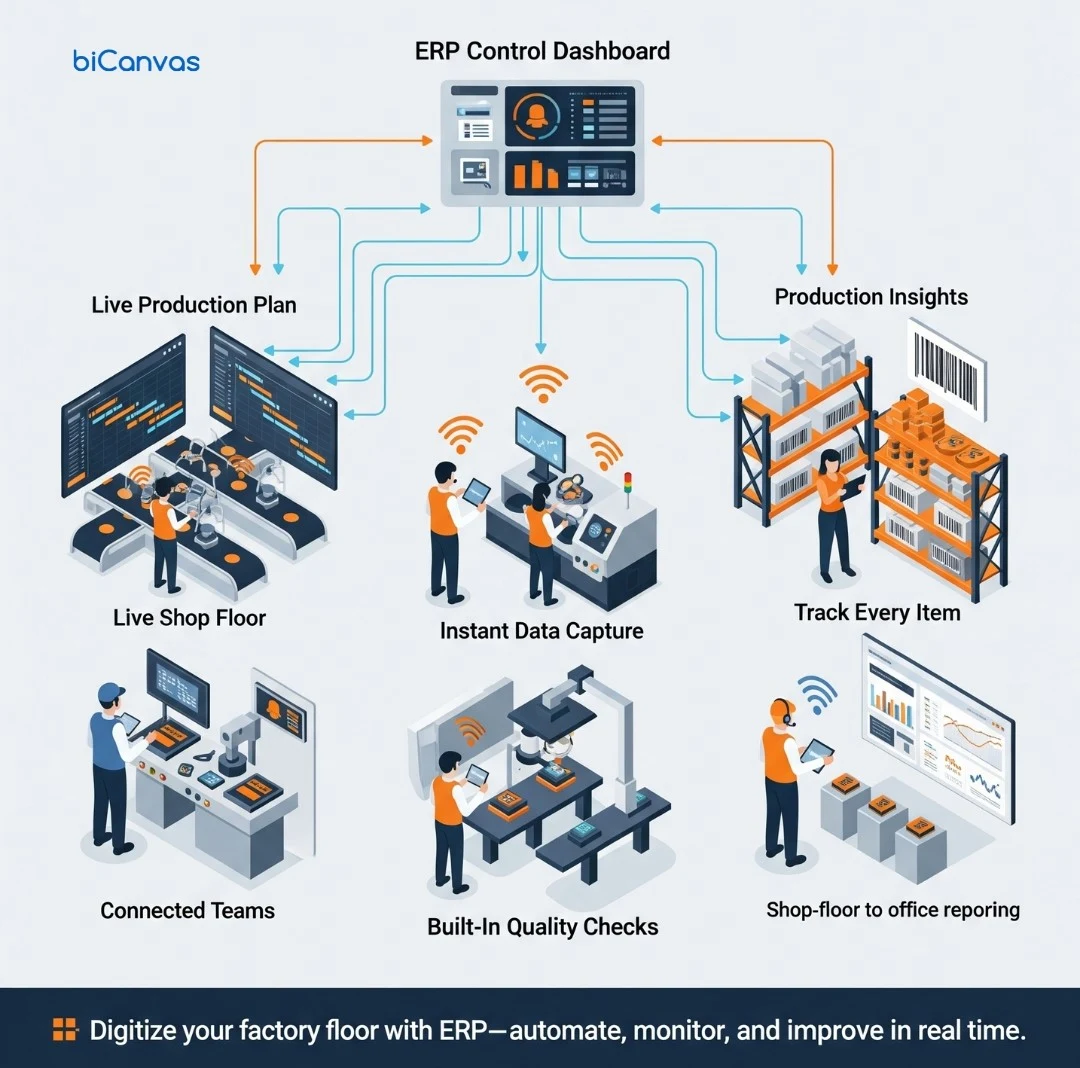

biCanvas is a purpose-built enterprise construction ERP for mid-to-large construction, infrastructure, EPC firms, and construction manufacturing. Focused on site-to-office integration, it removes data handoffs, reduces BOQ/WIP ambiguities, and delivers CFO-grade reporting.

Key Differentiators

Built-for-construction architecture — WBS, BOQ, WIP, procurement, equipment & asset lifecycle, preventive maintenance, contract management

Real-time site-to-HO visibility — Mobile-first, offline, approval workflows, location-tagged evidence

Advanced workflow & automation engine — Visual builder for multi-stakeholder approvals

Enterprise data & controls — Multi-entity consolidation, project-level P&L, role-based access, GST compliance

Integration ecosystem — Tally, Oracle, SAP, IoT/GPS, BI tools

Scalable cloud-native SaaS — With hybrid/private-cloud options

Domain-led UX — For field adoption

Implementation playbook & governance

Core Modules

Project Planning & Scheduling (WBS, Gantt)

BOQ & Estimation with Version Control

Work-in-Progress (WIP) & Daily Progress Reporting (DPR)

Procurement, Indent & GRN workflows

Subcontractor Management & RA Billing

Inventory & Material Reconciliation

Equipment & Asset Lifecycle + Preventive Maintenance (IoT-enabled)

Financials: Project Accounting, Cost Centers, Cashflow

HR & Payroll (integration-ready)

Document Management & RFI/Change Control

Analytics & Custom Dashboards

Core Modules to Look For in a Construction ERP

When evaluating a Construction ERP for a mid-to-large scale construction or infrastructure firm, these modules are essential. Together, they form the backbone of efficient project execution, financial control, asset management, and compliance.

Module / Capability

Why It Matters (Business Value)

Project Planning & Scheduling (WBS, Gantt, Multi-Project)

Lets you map out all tasks, dependencies, milestones across multiple projects. Enables realistic planning, workload balancing, and tracking of project timelines.

BOQ & Estimation with Version Control

Construction projects involve frequent changes in scope/quantities. Versioned BOQ management ensures all changes are tracked, approved, and reflected in budget and billing, minimizing disputes and cost overruns.

Work-in-Progress (WIP) & Daily Progress Reporting (DPR)

Real-time site-level updates (labor, material consumption, progress) ensure management visibility. Early detection of delays or overconsumption helps control cost and schedule.

Procurement, Indent & GRN Workflows

Standardizes procurement processes, prevents duplication, manages vendor communication, and ensures material supply aligns with project schedules — reducing delays and waste.

Inventory & Material Reconciliation (Site & Intersite Transfers)

Especially for multi-site companies or those with precast/RMC plants — tracks stock movement precisely, prevents theft or overuse, and ensures material availability.

Subcontractor / Vendor Management & RA Billing

Automates subcontractor billing, RA bills, approvals, and payment workflows — ensures transparency, avoids manual errors, and accelerates payment cycles.

Equipment & Asset Lifecycle / Maintenance (with IoT/Telematics support)

For firms with heavy machinery — tracks usage, maintenance, depreciation, preventive maintenance scheduling. Promotes better asset utilisation and reduces downtime.

Financial Management: Project-Level Accounting, Cost Centers, Cashflow & Project P&L

Enables accurate financial tracking across projects, cost centers, and entities. Helps management monitor profitability, cashflow, and overall financial health of operations.

HR & Payroll (

or Integration with Payroll System)

For firms handling large labor force — tracks attendance, payroll, labor costs, mobilization — essential for budget control and compliance with labor laws.

Document Management & Change Order / RFI / Variation Management

Construction projects involve many drawings, RFIs, revisions, approvals. Centralized document control ensures version integrity, audit trail, and fast access — reducing disputes and rework.

Reporting & Analytics / Custom Dashboards / KPI Monitoring

Real-time dashboards give management insight into project health, cashflow, resource utilisation, delays, costs vs budget etc. Enables proactive decisions rather than reactive firefighting.

Multi-Entity & Multi-Project Consolidation (Enterprise-ready)

For companies with multiple sites, entities, divisions — allows consolidated financials, inter-site transfers, centralized control, and standardized workflows.

Compliance & Statutory Modules (GST, Tax, Audit Trails, Regulatory Compliance)

In India, compliance with GST, accounting standards, tax rules, regulatory demands is mandatory. ERP must support statutory workflows to avoid penalties and maintain transparency.

Mobile Access & Offline Capabilities for Field Teams

Field engineers and site staff must be able to update progress even with unreliable connectivity. Offline-capable mobile apps ensure timely reporting and data accuracy.

Workflow Automation & Approval Engine

Enables customizable approval flows (for purchases, RA bills, subcontractor payments, change orders), ensuring process control, accountability, and audit readiness.

Integration Capability (Accounting Software, Payroll, IoT, GPS, BI Tools)

Construction companies often use multiple systems — ERP should integrate smoothly with accounting tools, payroll systems, equipment telematics, and BI analytics to avoid silos.

Implementation Timeline (Quick Reference)

Phase

biCanvas (Mid-Large Enterprise)

SAP S/4HANA

Oracle Construction Cloud

Procore

Discovery & Fit-Gap

2–4 weeks

4–8 weeks

4–6 weeks

2–4 weeks

Pilot (1–2 sites)

8–12 weeks

12–20 weeks

8–16 weeks

6–10 weeks

Rollout (Scale)

3–6 months

6–18 months

6–12 months

3–9 months

Stabilization

4–8 weeks

8–16 weeks

6–12 weeks

4–8 weeks

Total Cost of Ownership (TCO)

Components: Licensing, Implementation, Training, Integrations, Infrastructure, Support, Opportunity cost.

Indicative Bands:

Mid-sized multi-site (10–50 projects): ₹20–60 Lakh first-year TCO

Large enterprise (50+ projects, multi-site): ₹60 Lakh – ₹5 Cr+ first-year TCO

FAQ

1. What is construction ERP software and why do construction companies need it?

Construction ERP software is an integrated platform that manages BOQs, project execution, billing workflows, procurement, equipment, inventory, and site updates in real time. Construction companies rely on ERP systems to reduce cost overruns, track WIP accurately, manage subcontractor billing, and maintain compliance with GST and RERA standards.

2. Which is the best construction ERP software in India for real estate and infrastructure firms?

The best construction ERP software in India typically offers end-to-end modules like project planning, procurement, asset lifecycle, subcontractor management, and RERA-ready documentation. The top platforms ensure real-time visibility, faster decision-making, and predictable project execution across all sites.

3. How does ERP software for the construction industry improve project profitability?

An ERP software for construction industry improves profitability by eliminating leakages in material consumption, preventing billing errors, automating WIP tracking, and aligning site operations with budgeted BOQs. Real-time dashboards help identify delays or cost escalations before they impact margins.

4. What modules should the best ERP software for construction industry include?

A modern construction ERP should include project planning, BOQ management, WBS, WIP tracking, project billing, procurement management, vendor management, equipment tracking, asset maintenance, inventory control, HR & payroll, quality control, and compliance documentation.

5. How do construction management ERP software systems support multi-site operations?

Construction management ERP software centralizes project data across multiple locations, allowing head office teams to monitor progress, materials, budgets, and contractor performance in real time. It eliminates manual reporting and ensures project managers are aligned across sites.

6. Is there any free construction ERP software available for small contractors?

Free construction ERP software exists, but these platforms usually lack core modules like BOQ, procurement workflows, approval hierarchies, and subcontractor billing. Growing contractors prefer scalable, affordable systems that start small and expand as operations increase.

7. What is the difference between construction project management ERP software and standard ERP?

Construction project management ERP software is purpose-built for WBS, BOQ, site progress, equipment utilization, and subcontractor billing—unlike generic ERPs, which lack construction-specific features such as daily progress reports (DPRs), material reconciliation, or RA bills.

8. How do top construction ERP software providers ensure compliance with GST and RERA?

Leading construction ERP software providers include built-in compliance workflows for GST, RERA, and labour laws. The system generates audit-ready documents, maintains digital trails, and automates statutory reporting to avoid penalties and ensure transparency.

9. What should I look for when comparing top 10 construction ERP software in India?

When comparing the top 10 construction ERP software, evaluate modules, implementation time, mobile accessibility, integration capabilities, pricing transparency, customer support, and whether the platform is tailored to Indian construction workflows like RA bills and material gate entries.

10. How does ERP software for construction companies help with subcontractor management?

ERP software for construction companies automates subcontractor billing, tracks work orders against BOQ, ensures correct measurement entries, prevents overbilling, and records all revisions. It provides full transparency in contract value, scope, and work completion.

11. Does construction ERP software support real-time site-to-office communication?

Yes. Construction ERP software enables real-time communication through mobile apps where site teams update WIP, material receipts, and labor availability. Office teams get instant updates, eliminating WhatsApp and manual reporting delays.

12. How useful is construction ERP software for companies operating in UAE, Qatar, and Kuwait?

Construction ERP software for UAE, Qatar, and Kuwait supports local taxation, multilingual teams, and region-specific project workflows. It helps EPC, high-rise construction, and infrastructure contractors manage project documentation, budgets, and approvals per GCC norms.

13. What is included in construction ERP software modules for civil construction companies?

Civil construction ERP software modules include estimation, tendering, BOQ, RCC/structural work tracking, procurement automation, equipment logs, safety audits, DPRs, material reconciliation, and contract labour management.

14. How does construction ERP software help reduce project delays?

ERP systems reduce project delays by predicting material shortages, flagging schedule deviations, automating approvals, and giving project managers real-time performance analytics. Early alerts help teams avoid bottlenecks and maintain project timelines.

15. Is ERP implementation worth it for high-rise construction projects?

Absolutely. High-rise construction ERP software ensures accurate BOQ execution, phase-wise scheduling, tower-wise WIP tracking, concrete consumption monitoring, and automated billing cycles—critical for managing tower, slab, MEP, and finishing cycles efficiently.