Construction ERP Pricing in India 2026: Full Breakdown + Hidden Costs

Why Indian Construction Companies Are Finally Asking the Right Question

If you've been searching for "construction ERP pricing India" or "how much does construction ERP cost," you're already ahead of most competitors — because most construction companies in India never ask the cost question until they're deep in a bad implementation.

Construction ERP pricing in India ranges from ₹60,000 per year for lightweight tools to ₹25 lakh+ as a one-time cost for enterprise-grade, purpose-built solutions. The difference isn't just features — it's whether the ERP handles how Indian construction businesses actually operate: running account (RA) billing, BOQ-based procurement, GST/RERA compliance, multi-site tracking, and labour management under PF and ESI regulations.

This guide breaks down construction ERP cost in India across every dimension — licensing, implementation, training, customization, maintenance, and the hidden charges that blow up budgets after signing.

The 5 Cost Components Every Buyer Must Understand

Before comparing any construction ERP software price in India, know that every vendor quote is made up of the same five components — even if they don't present it that way.

1. Licensing Cost

Either a one-time perpetual license or a SaaS subscription. Construction ERP software price for licensing alone:

₹50,000–₹3 lakh/year for SaaS-based tools

₹5 lakh–₹15 lakh one-time for mid-market construction ERP

₹15 lakh–₹25 lakh+ one-time for enterprise ERP with full modules

2. Implementation Cost

Often equal to or greater than the license cost. For construction ERP in India:

₹1 lakh–₹3 lakh for basic implementations

₹3 lakh–₹8 lakh for mid-size firms with BOQ setup and data migration

₹8 lakh–₹20 lakh+ for enterprise multi-site implementations with Tally integration

3. Training Cost

Ranges from ₹50,000 to ₹3 lakh depending on team size and whether training is on-site or remote. Poor adoption is the number one reason construction ERP implementations fail in India — don't cut corners here.

4. Annual Maintenance Contract (AMC)

Covers software updates, bug fixes, and compliance updates for GST and labour law changes. AMC typically ranges from 15% to 25% of the license cost per year.

5. Infrastructure and Hosting

Cloud-based construction ERP bundles this into the subscription. On-premise requires server hardware (₹2 lakh–₹8 lakh) plus ongoing IT costs. Most Indian construction companies are moving to cloud for this reason.

Construction ERP Pricing by Company Size (India 2026)

Small Contractors (1–3 projects, 10–30 users)

Typical first-year cost: ₹3 lakh–₹8 lakh

Licensing: ₹60,000–₹2 lakh/year

Implementation: ₹1–₹2 lakh

Training: ₹30,000–₹75,000

Mid-Size Firms (4–15 projects, 30–100 users)

Typical first-year cost: ₹8 lakh–₹20 lakh

Licensing: ₹2–₹5 lakh/year (SaaS) or ₹3–₹8 lakh one-time

Implementation: ₹3–₹8 lakh

Training: ₹75,000–₹2 lakh

Enterprise / EPC Firms (15+ projects, 100+ users)

Typical first-year cost: ₹20 lakh–₹40 lakh+

Licensing: ₹10–₹25 lakh one-time

Implementation: ₹8–₹20 lakh

Training: ₹2–₹5 lakh

Not sure which tier fits your business? Book a free 30-minute demo with biCanvas — we'll give you a realistic cost estimate based on your actual project scale and team size. Book Free Demo

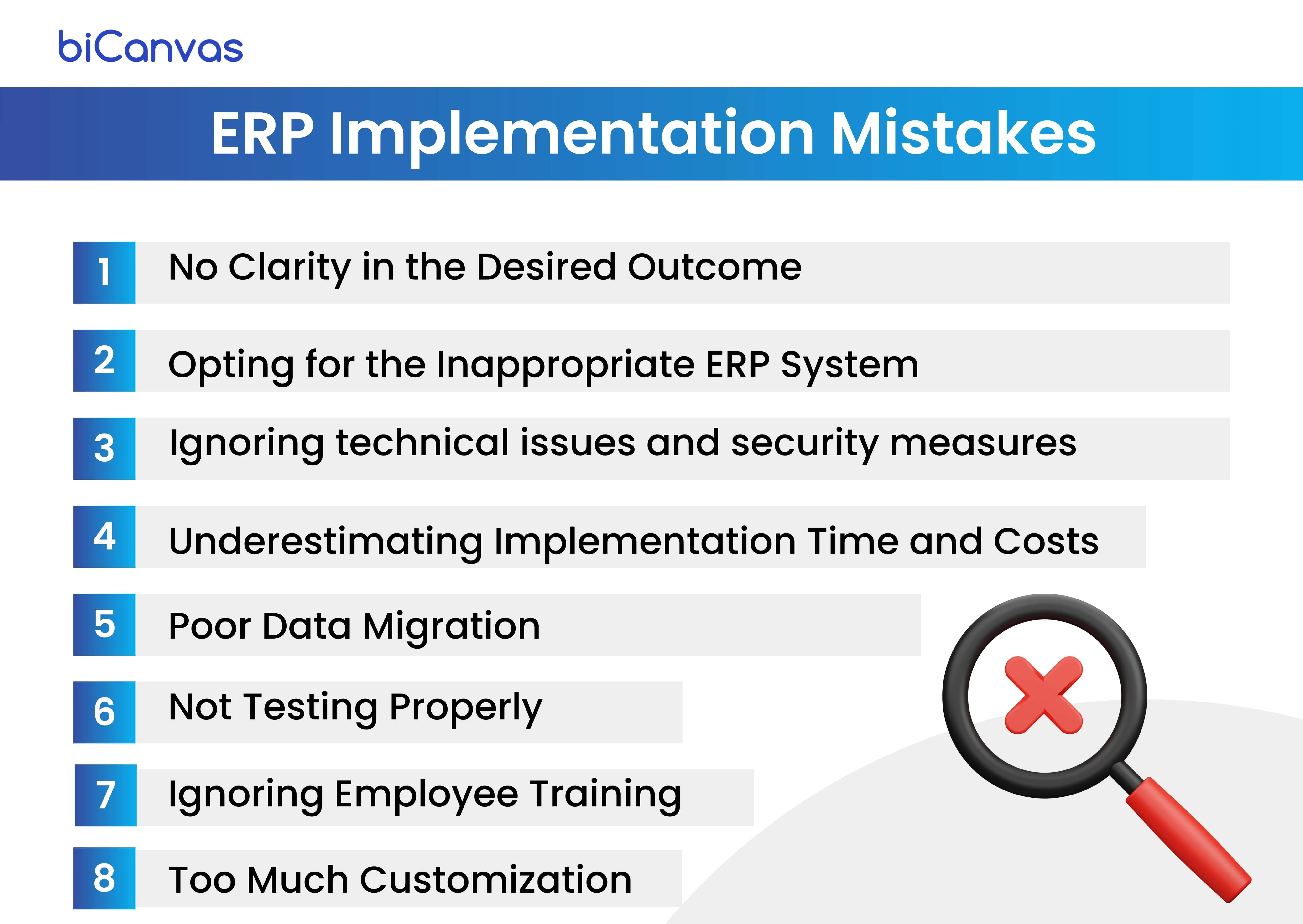

The Hidden Costs Nobody Tells You About

This is where most construction ERP pricing guides in India stop short. These are the costs that cause 30–40% budget overruns:

Customization Creep: Every non-standard workflow your team needs — custom approval flows, RA bill formats, site report templates — adds ₹50,000 to ₹5 lakh per customization. Document every requirement before signing.

Per-Module Pricing Surprises: Many vendors quote a base price covering only 3–4 modules. Equipment management, labour compliance, quality control, and BI dashboards are often charged separately at ₹1–₹5 lakh per module. Always ask for a full module list upfront.

Data Migration Complexity: If your data lives across dozens of Excel sheets and multiple Tally companies, migration alone can add ₹2–₹5 lakh to your project.

Additional User Licenses: Your initial quote covers 20 users — but site supervisors, store managers, and QC staff bring that to 40. Model realistic user numbers from day one.

Compliance Updates: Confirm that GST, TDS, and RERA compliance updates are included in the AMC. Some vendors charge separately for every regulatory change.

Site Internet Connectivity: Cloud ERP needs reliable internet at project sites. Budget for dedicated broadband, 4G dongles, or satellite connectivity at remote sites — this is a real cost many buyers miss.

Cloud vs On-Premise: Which Is Cheaper for Indian Construction Companies?

For most Indian construction companies in 2026, cloud-based construction ERP has a lower total cost of ownership over three to five years. Here is why:

On-premise requires a high upfront hardware investment, ongoing IT staff, and puts the burden of GST and regulatory compliance updates on your team. Cloud eliminates the hardware cost, includes compliance updates in the subscription, and gives site teams mobile access from anywhere — critical for multi-site construction operations across India.

The exception is large enterprise firms with existing IT infrastructure and strict data sovereignty requirements, where on-premise can still make sense.

India-Specific Costs: GST, RERA, and Tally Integration

Generic ERP pricing guides miss this entirely. Indian construction ERP buyers must account for:

GST for Construction: Works contracts attract 12–18% GST. Materials vary — cement at 28%, steel at 18%, bricks at 5%. Your ERP must handle works contract GST on subcontractor bills, ITC tracking across procurement, TDS deductions, e-invoicing, and state-wise filing. If this is not built in, you'll pay for manual CA reconciliation instead.

RERA Compliance: For RERA-registered projects, your ERP must generate progress reports in compliant formats and track fund utilisation against the 70% escrow requirement. This is non-negotiable for residential and commercial real estate contractors.

Tally Integration: Most Indian construction firms use Tally for accounts. Without clean ERP-to-Tally integration, you're running parallel systems with double data entry. A proper integration typically costs ₹50,000–₹1.5 lakh as part of implementation.

3-Year Total Cost of Ownership: A Real Example

TCO is the only number that matters when comparing construction ERP pricing in India. Here is a realistic example for a mid-size firm:

Cost Component

Year 1

Year 2

Year 3

Licensing (SaaS)

₹4,00,000

₹4,00,000

₹4,00,000

Implementation

₹5,00,000

—

—

Training

₹1,00,000

₹25,000

₹25,000

Infrastructure (cloud)

₹0

₹0

₹0

Customization

₹1,50,000

₹50,000

—

Total

₹11,50,000

₹4,75,000

₹4,25,000

3-Year TCO

₹20,50,000

Indian construction companies using purpose-built ERP typically report 10–25% reductions in cost overruns, 30–40% faster RA billing cycles, and near-zero GST reconciliation errors. For a firm with ₹50 crore in annual project turnover, a 10% reduction in overruns alone is worth ₹5 crore over three years.

Want a TCO estimate for your business? Book a free demo with biCanvas and we'll build it with you on the call.

Why biCanvas Is Built for Indian Construction Pricing Realities

biCanvas is purpose-built for construction, infrastructure, and EPC firms in India — not a generic ERP adapted for construction.

No customization tax: BOQ management, WBS tracking, RA billing, subcontractor management, and site progress reporting are native modules — not paid add-ons.

India-ready compliance: GST works contract calculations, TDS, e-invoicing, RERA reporting, PF and ESI labour compliance, and Tally integration are all included.

Mobile-first: Site teams update progress, raise material requests, and capture data from Android or iOS — with offline sync for low-connectivity sites.

Faster implementation: Because biCanvas is pre-configured for construction workflows, implementation timelines are shorter than generic ERP — meaning lower implementation cost and faster ROI.

FAQ: Construction ERP Pricing in India

What is the average cost of construction ERP in India in 2026? Construction ERP pricing ranges from ₹60,000/year for basic tools to ₹25 lakh+ one-time for enterprise solutions. A realistic all-in first-year cost for a mid-size firm is ₹8–₹20 lakh including implementation and training.

What hidden costs should I watch for? Module add-ons, customization charges, additional user licenses, data migration complexity, compliance update fees outside AMC, and site internet connectivity costs are the most common budget surprises.

Does construction ERP include GST and RERA compliance? Purpose-built solutions like biCanvas include this as core functionality. Generic ERP solutions typically require expensive add-ons or manual workarounds to achieve the same coverage.

How long does implementation take? 6–8 weeks for smaller firms, 3–6 months for mid-size multi-site operations, and 6–12 months for large enterprise implementations.

Can small contractors afford construction ERP? Yes. Cloud-based construction ERP starts from ₹60,000–₹2 lakh per year for small firms with minimal implementation cost. The key is choosing a purpose-built construction tool rather than a generic ERP that requires heavy customization.

Ready to Get a Real Price for Your Business?

Pricing ranges are useful — but what you actually need is a number based on your specific project scale, team size, compliance requirements, and growth plans.

In a free 30-minute biCanvas demo, our construction ERP specialists will walk you through the modules relevant to your business, give you a realistic cost estimate and implementation timeline, and answer your questions about GST, RERA, Tally integration, and site mobile access.

Book Your Free Demo →

_1771566708.webp)